3D metal printing – done by yourself

Trust the process expert with > 1 million produced tooth units

Learn easily with us the entire process from the design to the finished metal crown.

Since 2011 we have been producing in the laser melting process for labs. We will share all the tips and tricks with you to help you to get off to a smooth start. Soon you will be able to buy i-ProMelt Powder in our Online-Shop.

i-ProMelt Powder – perfectly matched with the

CORiTEC® AM series

The i-ProMelt Powder ist a certified and quality-tested powder for the CORiTEC® AM100 and its parameters to set up dental applications.

The powder container also serves as a supply container in the machine – the material can be fed directly into the process, without cumbersome filling of cylinders or building chambers of the machines.

Highly complex frameworks can be built with i-ProMelt. Thus, i-ProMelt forms the perfect basis for a variety of veneering ceramics and composite build-ups, such as removable partial denture frames.

Your benefits:

- A particle size distribution of 10 – 30 µm

- Excellent processing properties

- Due to the type 5 alloy to DIN EN ISO22674 perfectly suitable for highly complex frameworks, such as superstructures, removable partial denture frames, primary and secondary parts as well as crowns and bridges

- Perfect base for a wide range of veneering ceramics due to a CTE value of 14.5 (20 – 500 °C)

- Optimal handling of the powder material due to suitable containers for the CORiTEC® AM cartridge system (PU 5 kg)

More informationen on the CORiTEC® AM-series

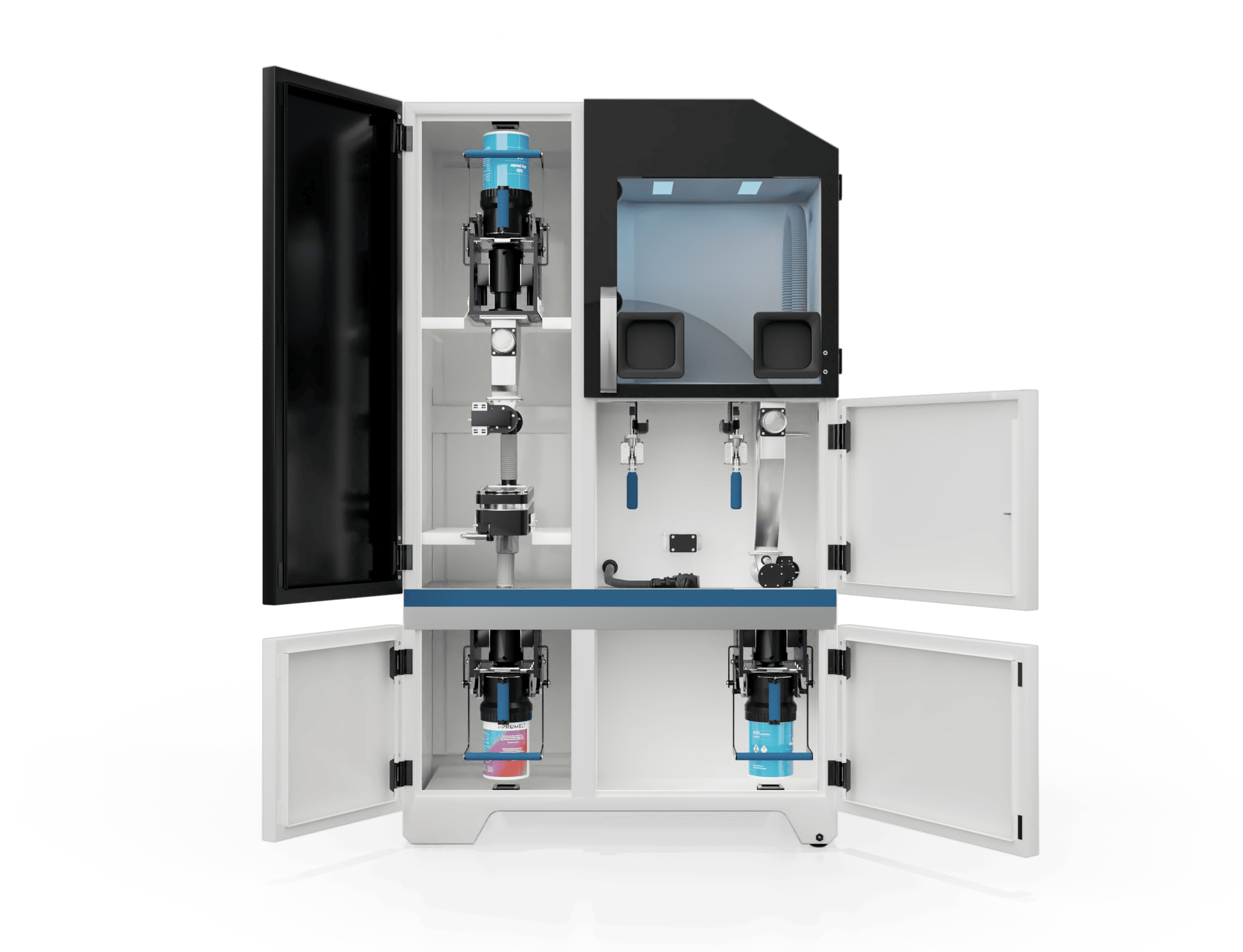

Together with the metal printing machine there is a special software, an unpacking and sieving unit as well as other components.

The CORiTEC® AM100 metal 3D printer

is the fast and affordable entry into additive dental production. The production of up to 250 tooth units per processing cycle sets new standards.

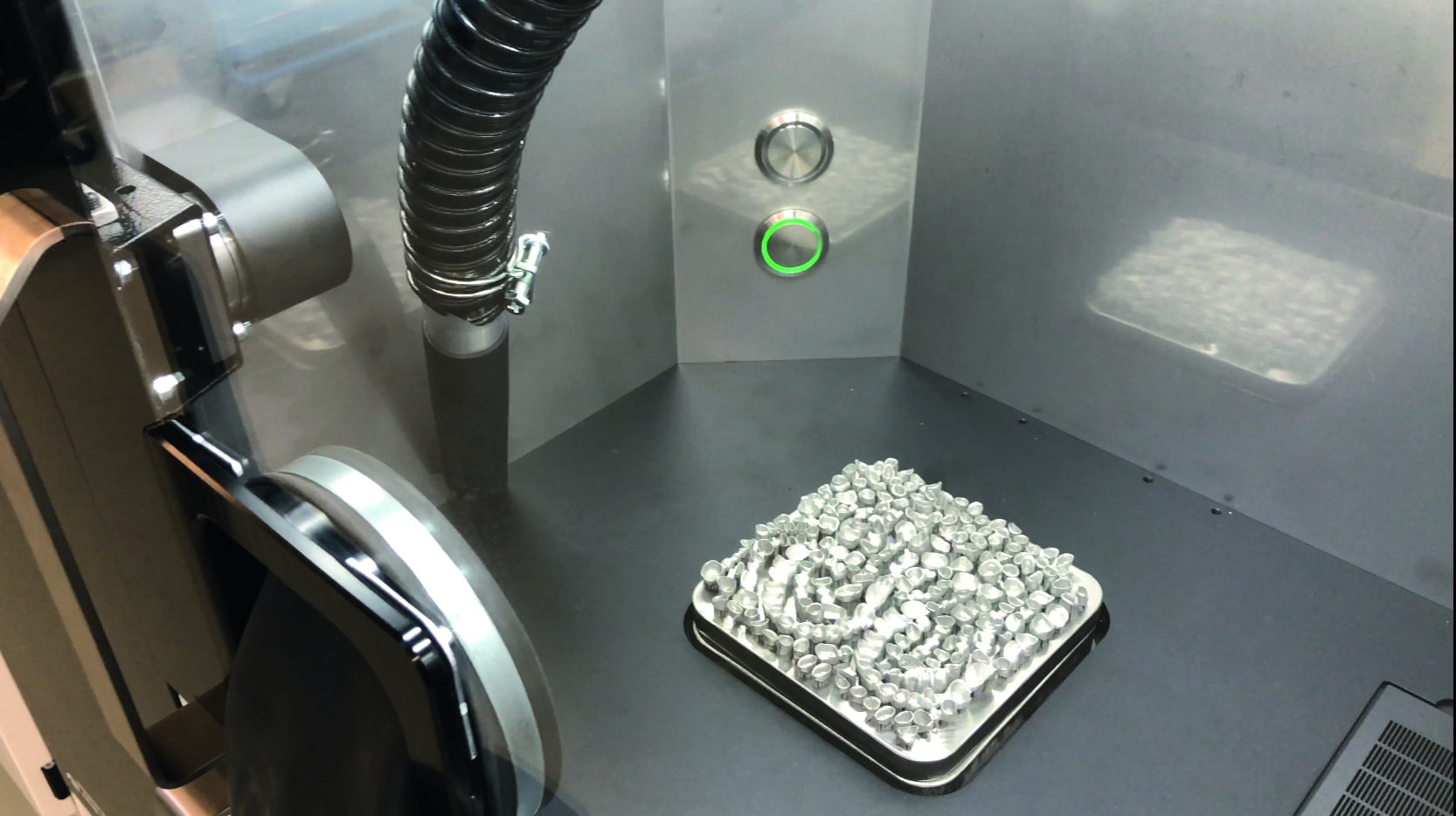

The CORiTEC® AMpure unpacking and sieving station

prepares material for reuse. The door of the chamber has two integrated gloves. This makes it possible to unpack the components without any powder contact.

Your benefits:

- Printing time per tooth unit < 3 minutes

- Up to 250 dental units per processing cycle

- Easy machine operation through intuitive step-by-step software and touchscreen

- Optimal process monitoring by integrated camera and remote connection

- Integrated 5-fold powder supply

- Loading of the machine with prepared/new powder during the ongoing production process

Your benefits:

- Unpacking the components without direct powder contact due to glove intervention

- Massive material savings by recycling the sieved powder

- Optimal powder preparation by intelligent ultrasonic sieving station

- Innovative powder management including compatible overflow and supply cartridges.

- Comfortable cleaning due to connection for the suction system

- Easy disposal of the oversized particles through a separated collection container

How does powder dosing and processing work?

The powder is added from the supply cartridge of the 5-fold loader. The overflowing powder is collected in the overflow cartridge. What happens next?

Take a look for yourself:

More information can be found in the product brochure in the download area:

What additional accessories are required?

Suction unit, annelaing furnace and metal band saw are needed for complete processing your frameworks. We have everything for you and also configure the device for an optimal application with the CORiTEC® machines. If you want to have a nitrogen generator, we will deliver that too.

Suction unit

For cleaning the building platform in the CORiTEC® AMpure unpacking and sieving station

Annealing furnace

For stress-relief annealing of the produced frameworks on the building platform

Metal band saw

For separating the produced frameworks from the building platform

Nitrogen generator

For easy production of nitrogen and for avoiding the constant exchange of cylinders

How to reach us:

+49 6181 6766899

info@i-prodens.com

We are here for you:

Mo - Fr 8:00 a.m. - 12:00 p.m

and 1:00 p.m. - 5:00 p.m. CET

Order Portal:

Online-Shop:

Certificate

Here we are:

i-ProDens GmbH | Hanau | Germany